10.106 CONCRETE PERMEABILITY

High Reactivity Metakaolin (HRM)

Engineered Mineral Admixture for Use With Portland Cement

Advanced Cement Technologies’ PowerPozz™ High Reactivity Metakaolin is a manufactured pozzolanic mineral admixture, which significantly enhances many performance characteristics of cement-based mortars, concretes and related products.

PowerPozz™, derived from purified kaolin clay, is a white, amorphous, alumino-silicate, which reacts aggressively with calcium hydroxide to form compounds with cementitious value.

Produced under ISO 9002 conditions, PowerPozz™ is subjected to strict process quality control to assure product uniformity and consistent performance.

Used at 5 -15% replacement of cement by weight, PowerPozz™ will contribute to: increased strength; reduced permeability; greater durability; and effective control of efflorescence and degradation caused by Alkali-Silica Reaction (ASR).

Concrete Durability

A concrete structure is considered to be of adequate durability if it performs in accordance with its intended level of functionality and serviceability over an expected or predicted life cycle. Durable concrete must have the ability to withstand the potentially deteriorative conditions to which it can reasonably be expected to be exposed.

Concrete deterioration can be due to adverse mechanical, physical, or chemical causes. It is often the case where one or more deteriorative mechanisms are at work by the time a problem is identified. In fact, in terms of deterioration of concrete due to physical or chemical causes, the mobility of fluids or gases through the concrete are nearly always involved. The overall susceptibility, or penetrabilityof a concrete structure, especially when compounded by additional environmental or exposure challenges, is thekey to its ultimate serviceability and durability.

Low porosity / permeability / penetrability of concrete to moisture and gas is the first line of defenseagainst: frost damage, acid attack, sulfate attack, corrosion of steel embeddments and reinforcements, carbonation, alkali-aggregate reaction, and efflorescence to name a few of the most prominent concrete ailments.

Concrete Permeability

Concrete durability depends largely on the ease (or difficulty) with which fluids (water, carbon dioxide, oxygen) in the form of liquid or gas can migrate through the hardened concrete mass. Concrete is a porous material. Therefore, moisture movement can occur by flow, diffusion, or sorption. We are concerned with all three, but generally the overall potential for moisture and ion ingress in concrete by these three modes is referred to as its permeability.

Concrete Porosity

The aspect of properly consolidated, quality, hardened concrete that affects its permeability is the nature of the hardened cement paste itself and, as well, the nature of the interfacial zone between concrete “macro components”, (i.e.: aggregates, reinforcing materials, fibers) and its cement paste structure. The paste-aggregate interfacial zoneis known to be different from the cement paste mass in general. It is usually more porous, richerin Ca(OH)2 (calcium hydroxide),and is moreprone to micro cracking than the rest of the paste matrix. The interfacial zone is normally in the order of 50 um in thickness, and can occupy 30 -50% of the total volume of cement paste in concrete. In comparison to the bulk hydrated cement paste, the paste-aggregate interfacial zone is weaker, more soluble, and can be a least resistant path for migrating moisture and other harmful substances.

It should be noted that although aggregates are porous, their pores are normally discontinuous in a concrete matrix, being completely enveloped by cement paste.

Discrete voids or pores in concrete, including entrained air bubbles that are discontinuous similarly do not contribute significantly to concrete permeability.Concrete porosity is usually expressed in terms of percentage by volume of concrete. It is the interconnectivity of pores, rather that total porosity that determines a concrete’s permeability.

A concrete with a high proportion of disconnected pores may be less permeable that a concrete with a much smaller proportion of connected, or continuous pores. With greater particularity, it is the overall nature of the matrix pore structure that ultimately affects its permeability, sorptivity, and diffusivity. The size, distribution, interconnectivity, shape, and tortuosity of pores are all determining factors in the overall permeability of a concrete matrix.

Waterproof or watertight Portland cement concrete is not a real possibility. Instead, our goal in design and formulation of durable concrete mixes is to slow and minimize the potential for, and rate of, moisture ingress and movement.

Effect of Pozzolan on Porosity / Permeability

Experts have widely agreed for decades that the use of pozzolana, or supplementary cementing materials, can reduce concrete permeability by 7 to 10 times. In particular the mechanism of pozzolana in this role can be viewed as having two principal aspects. First, the use of aquality pozzolan will result in a denser pore structure in the cement paste matrix. Second, the chemical reaction of lime crystals to form binders has a direct effect of increased paste density, reduced porosity over time, and will enhance the matrix chemical resistance to many aggressive species.

Effect of PowerPozz HRM on Porosity

The effect of High Reactivity Metakaolin in this regard is pronounced. The engineered particle size of HRM serves as an effective micro-packing additive. Its average particle size being approximately one order of magnitude smaller than

the average cement particle, it will serve to fill the interstitial spaces between cement grains, thus physically tightening the particle arrangement. In addition, the optimized reactivity of HRM serves to chemically combine with calcium hydroxide. The alteration of lime is in a way a removal by substitution reaction, where calcium hydroxide crystals are reacted by HRM, in the presence of moisture, to form durable binding products such ascalcium silicate and calcium aluminate hydrates. The physical and chemical effect of HRM is of particular significance with regard to the paste-aggregate interfacial zones mentioned previously.

The pore size distribution is affected by HRM. Generally, the total pore volume is reduced and the average pore size is decreased. There is a significant decrease in the occurrence of very fine pores (0.01 -0.10 um) in an HRM paste as compared to plain OPC.

Chloride Ion Permeability

The resistance of HRM concrete to chloride-ion penetration is significantly higher than plain OPC of Fly Ash concrete, and similar to that of silica fume concrete.

There are two predominant tests used to determine concrete’s permeability to chloride ions and other aggressive solutions:

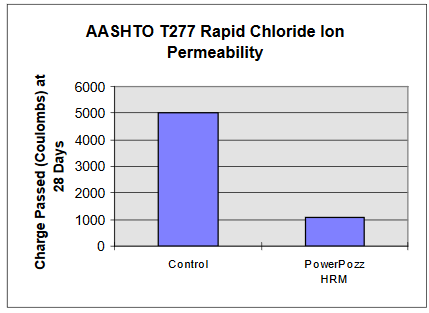

- The American Association of State Highway and Transportation Officials (AASHTO) Test Method T277, Rapid Determination of the Chloride Permeability of Concrete.

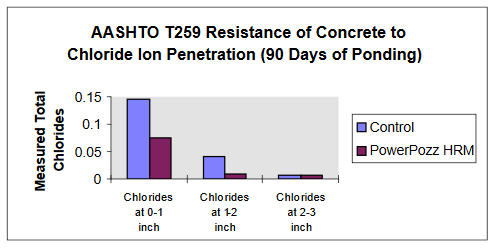

- Test Method T259 Resistance of Concrete to Chloride Ion Penetration.

The AASHTO T259 (90 Day Ponding) test has long been favored by concrete corrosion specialists, but the need for a faster and less costly method has given the T277 (Rapid Chloride Permeability Test -RCPT) a recent rise in popularity. Presently, the RCPT is common in durability specifications, with results being expressed in units of coulombs are specified in the 700 to 1500 coulomb range for concretes tested at ages between 28 and 56 days of maturity.

Recent critical reviews of the RCPT have created many debates concerning the reliability, usefulness, and appropriateness of the test method itself and its results. Importantly, the need for correlation of results to the 90 Day Ponding method has been raised.

Effect of PowerPozz High Reactivity Metakaolin

As part of a broad-based review of PowerPozz performance in High Performance Concrete (HPC) mixes, the effect of PowerPozz HRM on both the AASHTO T277 & T259 tests were established. Testing was carried out at Construction Technology Laboratories (CTL) in Skokie, IL.

Testing

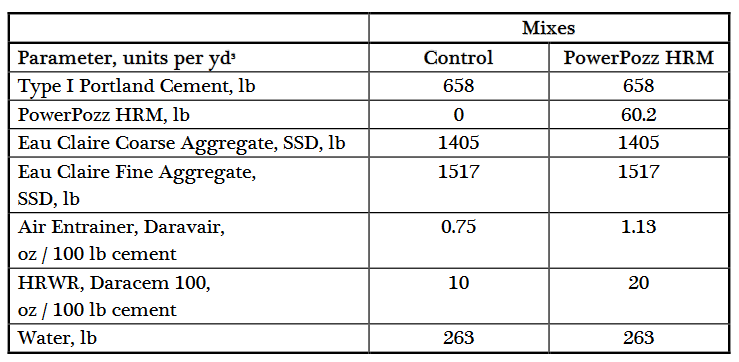

Testing was carried out in accordance with the AASHTO methods. The mix design is indicated in the table below.

The results clearly demonstrate the positive effect of PowerPozz in improving the chloride penetration resistance of concrete.

Reinforcing Steel Corrosion

Ingressing water that contains soluble chloride ions can result in steel depassivation. In a depassivied state, in the presence of water and oxygen, steel will corrode rapidly. The corrosion of steel is accompanied by expansive pressures, which lead to cracking. The cracked matrix is then severely compromised. An escalating and irreversible process of deterioration follows.

The development of low permeability concrete, with a heightened resistance to chloride ion ingress holds the key to corrosion protection. High Reactivity Metakaolin will substantially increase a concrete’s resistance to chloride ingress by contributing to:

- Reduced overall permeability (to water, salt solutions, vapor, gases)

- Reduced chloride ion permeability

- Reduction in size, and stabilization in chemistry of paste /steel interfacial zone

- Reduce chloride content in pore water

- Mitigated cracking caused by shrinkage and ASR

- Maintenance of pore solution pH (>12.5)

The permeability of concrete may be the most important of its properties that affects its ultimate serviceability and durability. This aspect of performance design, especially where first-time and long term life-cycle costs are major

considerations, must be taken with due seriousness. This holds particular importance for major infrastructural projects and/or projects which will subject its concrete components to aggressive environments or exposure conditions. Worth specific mention for example are: bridge members and decks, parking structures, offshore and marine structures, pavement or repair overlays, building components, water resource facilities, and the like.

PowerPozz High Reactivity Metakaolin offers the means to achieve the desired engineering properties of high performance, extended durability concrete with a minimum of side effects or special handling constraints. Easy to use, and offering ISO 9002 certified, manufactured, consistent performance qualities, PowerPozz offers a leading edge solution to the next centuries’ concrete engineering challenges.

Referenced Documents:

CTL Test Report to Advanced Cement Technologies. September 1997John J. Meyers; Wissam E. Touma; Ramon L. Carrasquillo: Dept. of Civil Eng. The University of Texas at Austin. “Permeability of High Perfromance Concrete: Rapid Chloride Ion Test vs Chloride Ponding Test.” Presented at PCI / FHWAInternational Symposium on High Performance Concrete. New Orleans, Oct. 1997.Neville, A.M. “Properties of Concrete” Fourth Edition Wiley & Sons 1996

All information, while provided in good faith, with every effort made to assure accuracy, is provided at no charge, and without warranty -express or implied. Data given, unless otherwise stated, are based on standard testing procedures which are available on request. Variations do occur in individual tests and the results stated herein cannot be taken for maxima or minima for specification purposes.

As we cannot anticipate all possible applications of our products, nor variations in manufacturing equipment, formulae, methods, or practices, we guarantee only that the products will meet the specifications of Advanced

Cement Technologies at the time of sale. Advanced Cement Technologies reserves the right to change specifications should it become necessary. Products are sold without warranty, express or implied, with all warranties of fitness of purpose and merchantability being disclaimed, and on condition that the purchaser is responsible for the determination of each product’s suitability for a particular purpose.

Statements concerning the possible use of our products are not intended as recommendations for use. No liability is accepted by Advanced Cement Technologies for any infringements of any existing or future patents.

Products sold, unless otherwise stated, will be subject to the general terms and sales conditions of Advanced Cement Technologies.