10.104 – ALKALI-SILICA REACTION (ASR)

High Reactivity Metakaolin

Engineered Mineral Admixture for Use with Portland Cement

Advanced Cement Technologies’ PowerPozz™ (a High-Reactivity Metakaolin) is a manufactured pozzolanic mineral admixture which significantly enhances many performance characteristics of cement-based mortars, concrete, and related products.

Derived from purified kaolin clay, PowerPozz™ is a white, amorphous, aluminosilicate which reacts readily with calcium hydroxide to form compounds with cementitious value.

Background – The ASR Problem

Quality concrete is a carefully selected composition of materials which, when properly manufactured, proportioned, mixed, placed, consolidated, finished and cured will have sufficient strength and durability in accordance with the desired application. Unfortunately, a problem exists and has long been identified where cement alkalis, while being important to the concrete’s strength development, can be, under certain circumstances, principally and directly contributory to degradation and loss of durability.

ASR can be explained as the situation where cement alkalis react with certain forms of silica in the aggregate component of a concrete, forming an alkali-silica gel at the aggregates surface. This formation, often referred to as “reaction rim” has a very strong affinity for water, and thus has a tendency to swell. These expanding compounds can cause internal pressures sufficiently strong to cause cracking of the paste matrix, which can then result in a compromised concrete with an open door to an increasing rate of deterioration.

For the alkali silica reaction to occur and produce a potentially expansive gel, Ca, OH, reactive silica, water, and soluble metal alkali ions need to be present. The Ca(OH)2 is the free lime by-product of ordinary portland.

cement (OPC) hydration. Reactive phases of silica are found in some sources of construction aggregates with wide regional variations. The soluble alkali ions may be present in the pore solution of the concrete (the amount being primarily dependent on cement alkalinity) and/or from external sources of salts such as seawater, or road de-icing substances.

The worldwide costs of ASR degradation are extremely high. Regional manifestations of these costs are seen in: remedial repairs in already deteriorating structures; new construction (where costs are impacted dramatically in use in imported, low-alkali cement and /or imported non-reactive aggregates); and in the less tangible impact on structure life cycle and overall owner and user utility.

The PowerPozz™ Solution

When a pure form of Metakaolin is employed as a pozzolanic mineral admixture at 10 -15% weight of cement, the calcium hydroxide level can be reduced sufficiently to render any gels that are formed as non-expansive (1,2). The protection is further enhanced in view of the Metakaolin addition’s effect on overall reduced concrete permeability and in a slight reduction in the alkalinity of the pore solution.

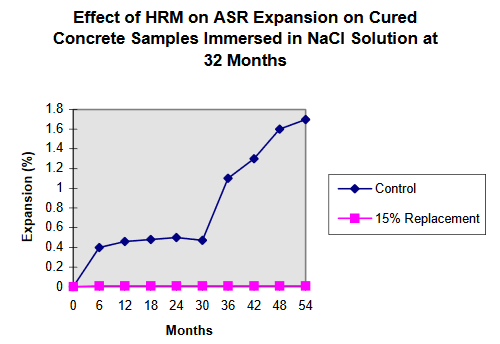

Figure 1, illustrates the research by Jones et al (1,2) and shows the effect of High Reactivity Metakaolin in mitigating the expansion that is very clearly the result in control (plain OPC) samples under the same curing and exposure conditions. After 32 months of curing at 100% relative humidity, the control and HRM samples were immersed in a saturated sodium chloride solution to induce expansion. The expansion is eliminated in this study at a 15% replacement of cement by weight with a HRM.

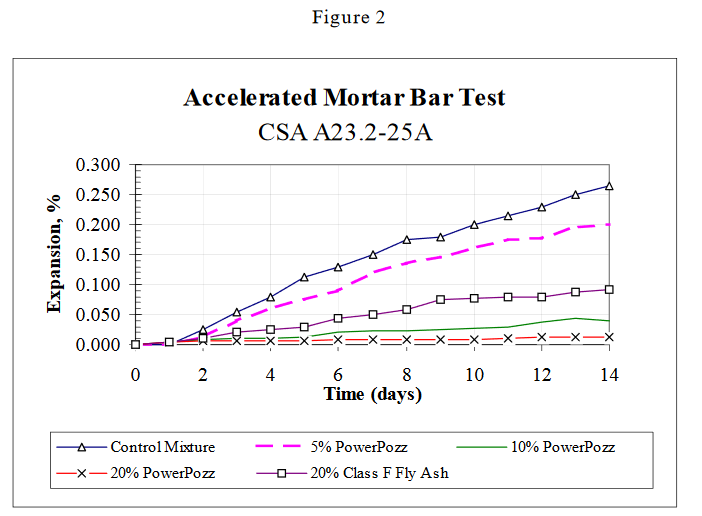

Tests have been performed using PowerPozz™ HRM to study the potential to mitigate the effects of ASR in mortar bars. The study reported here, conducted by Jacques Whitford and Associates, was performed in accordance with Canadian Test Standard CSA A23.2-25A (Accelerated Mortar Bar Test) which is similar to ASTM C1260. The evaluation was under the direction of Mr. Wilbert S. Langley (3). Results are illustrated in Figure 2.

The test involved a control (plain OPC) mix, a 20% Class F flyash mix, and PowerPozz™ mixes at 5, 10, and 20% replacement. The results show that with a known very reactive aggregate, PowerPozz™, at 10%, dramatically reduced the expansion versus the control and flyash formulations. At 20%, expansion was virtually eliminated.

Referenced Documents:

-

- Jones, T.R. , Walters, G.V., and Kostuch, J.A. 9th International Conference on AAR in Concrete, v.1, 1992, pp. 485-496.

- Walters, G.V., and Jones, T.R. 2nd International Conference on Durability of Concrete, Canada, ed. V.M. Malhotra, 1991, pp. 941-953.

- Test Report – Jacques Whitford Materials Ltd., August 29, 1995.

All information, while provided in good faith, with every effort made to assure accuracy, is provided at no charge, and without warranty – express or implied. Data given, unless otherwise stated, are based on standard testing procedures which are available on request. Variations do occur in individual tests and the results stated herein cannot be taken for maxima or minima for specification purposes.

As we cannot anticipate all possible applications of our products, nor variations in manufacturing equipment, formulae, methods, or practices, we guarantee only that the products will meet the specifications of Advanced Cement Technologies at the time of sale. Advanced Cement Technologies reserves the right to change specifications should it become necessary. Products are sold without warranty, express or implied, with all warranties of fitness of purpose and merchantability being disclaimed, and on condition that the purchaser is responsible for the determination of each product’s suitability for a particular purpose.

Statements concerning the possible use of our products are not intended as recommendations for use. No liability is accepted by Advanced Cement Technologies for any infringements of any existing or future patents.

Products sold, unless otherwise stated, will be subject to the general terms and sales conditions of Advanced Cement Technologies.